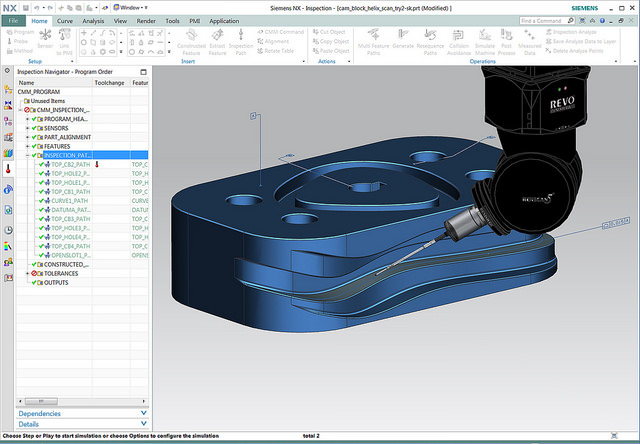

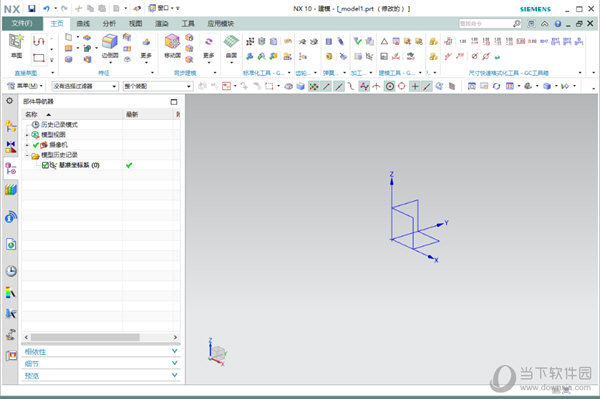

The first four chapters of this book cover the user interface, part modeling, assemblies, and drawings. The Author guides readers through NX 10 with clear and step-by-step tutorials that help you to design solid models from day one. Layers also can be used for drafting for Visible in view. NX 10 Tutorial is written to help new users to learn the basics of NX and some advanced solid modeling techniques. Final part if you choose will be on layer one. Layers can be used with sketches keeping them on other layers as the user develops design intent of the final part. Reference sets are used to capture what you really want the model to show at another level. Separates annotation data from the UG-MasterĪ user can load the master assembly without needing to load the drawing/spec data into the session, improving load times and reducing memory usage. A unique assembly design and mockup environment, process specific design aids, drafting and 3D. A comprehensive mechanical design and manufacturing solution, NX lets you choose the tools and methodologies that best suit your design challenge, and work directly with design data from other CAD systems.

#UNIGRAPHICS NX 10 PDF#

Promotes concurrent engineering by enable a user top modify the drawing/spec without locking the UG-Master part file.ĭrafting and modeling changes can happen in parallelģ. Unigraphics Nx 10 Book Free Pdf Download.

Instead of creating the drawing/spec in the part file itself, creates a non-master Spec in Teamcenter Or Folder that references the UG-Master.Ģ. The following are a few advantages of applying the Master Model Strategy concept to everyday design.ĭrawings/Spec files are separate files from At the end of this process, all six robots communicate with the material handling robot to determine good or bad part.Master Model Strategy is an important concept in the design industry.

#UNIGRAPHICS NX 10 SOFTWARE#

The nuts go in and are crimped using amperage as an indicator if the nut is properly secured. Photo & Graphics tools downloads - Siemens NX by Siemens PLM Software and many more programs are available for instant and free download. The handling robot then moves the part to the rivet nut station where two robots apply 66 float nuts, fed to the robots via a pneumatic tube. Each robot has a vacuum unit at its head and collects the dust during the routing process. In 2000, Unigraphics purchased SDRC I-DEAS and began an effort to integrate aspects of both software packages into a single product which became Unigraphics NX or NX.

#UNIGRAPHICS NX 10 64 BIT#

The wall then rotates 180 degrees and a handling robot picks up the part and places it into the route cell where four robots cut about 65 holes. unigraphics nx 10 rus 64 bit org That is on the Cloudflare network cloudflare is currently unable to resolve your DNS error 1016 Ray. NX, formerly known as 'unigraphics', is an advanced high-end CAD/CAM/CAE, which has been owned since 2007 by Siemens PLM Software. The part is clamped in place, the part style verified via a sensor, and several holes are drilled.

The process starts with the operator manually loading the part on a wall fixture where the automated cycle then starts. Tooling Tech developed a solution that could route all the holes in a single orientation during a continuous process while using a minimum amount of floorspace. NX Realize Shape provides an integrated toolset for sculpting advanced product forms in NX.

Aesthetic surfacing with NX Realize Shape. The API reference guides for the various languages is included in the NX help files however, the programming help is not installed by default. unigraphics-nx-10-tutorial-pdf 1/1 Downloaded from on Februby guest Kindle File Format Unigraphics Nx 10 Tutorial Pdf Yeah, reviewing a book unigraphics nx 10 tutorial pdf could increase your close links listings. The customer thought it would take four machines to accomplish this. NX 10 and later support Python as an automation language. In addition, they wanted a fully automated solution with +0.25mm tolerance on the holes, zero dust emission and a cycle time of just over three minutes. Our customer needed to produce two versions of a composite automotive part that required the routing of 100 holes and the application of 65 float nuts along with some rivet studs.

0 kommentar(er)

0 kommentar(er)